Prefabrication

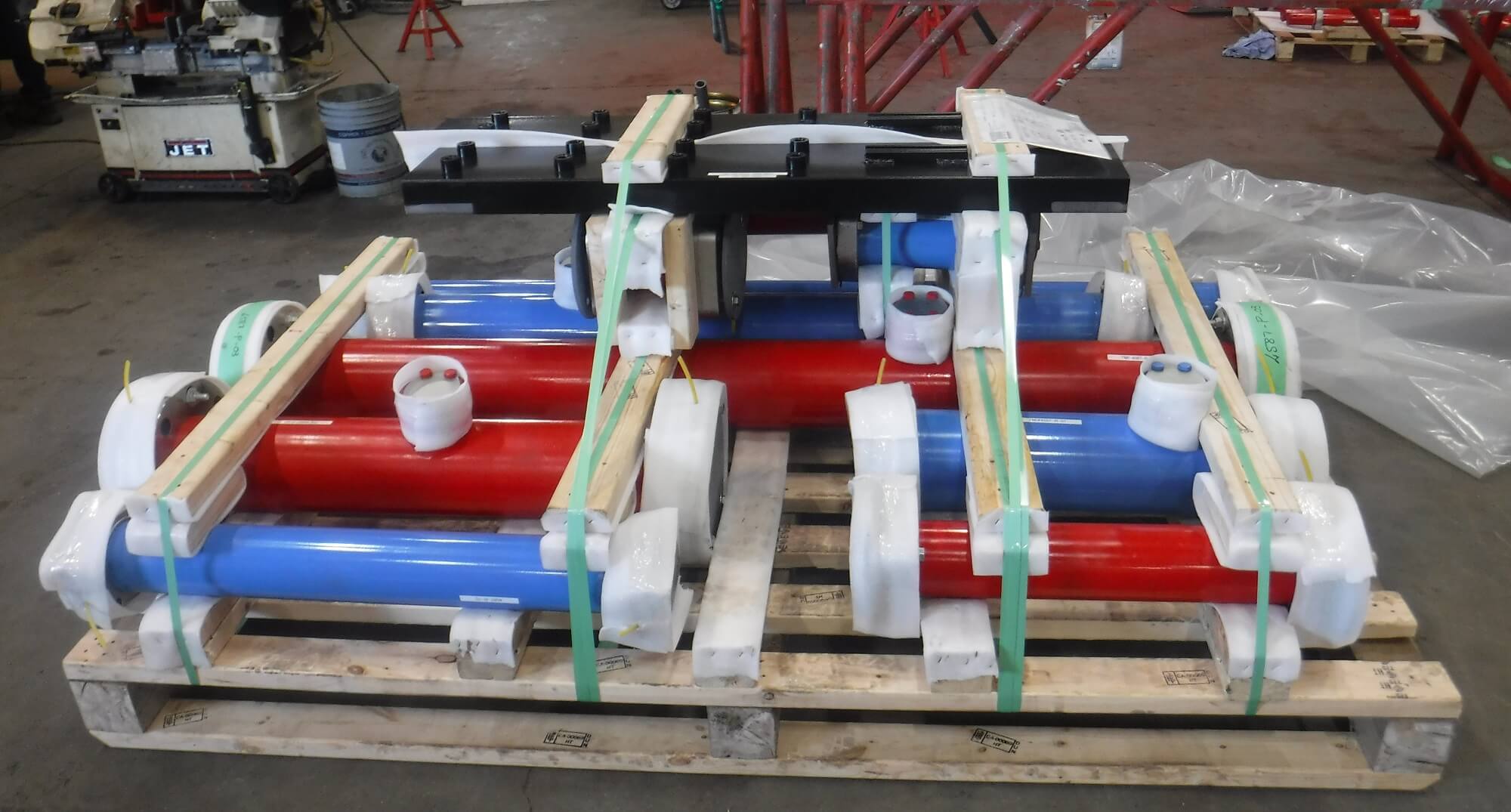

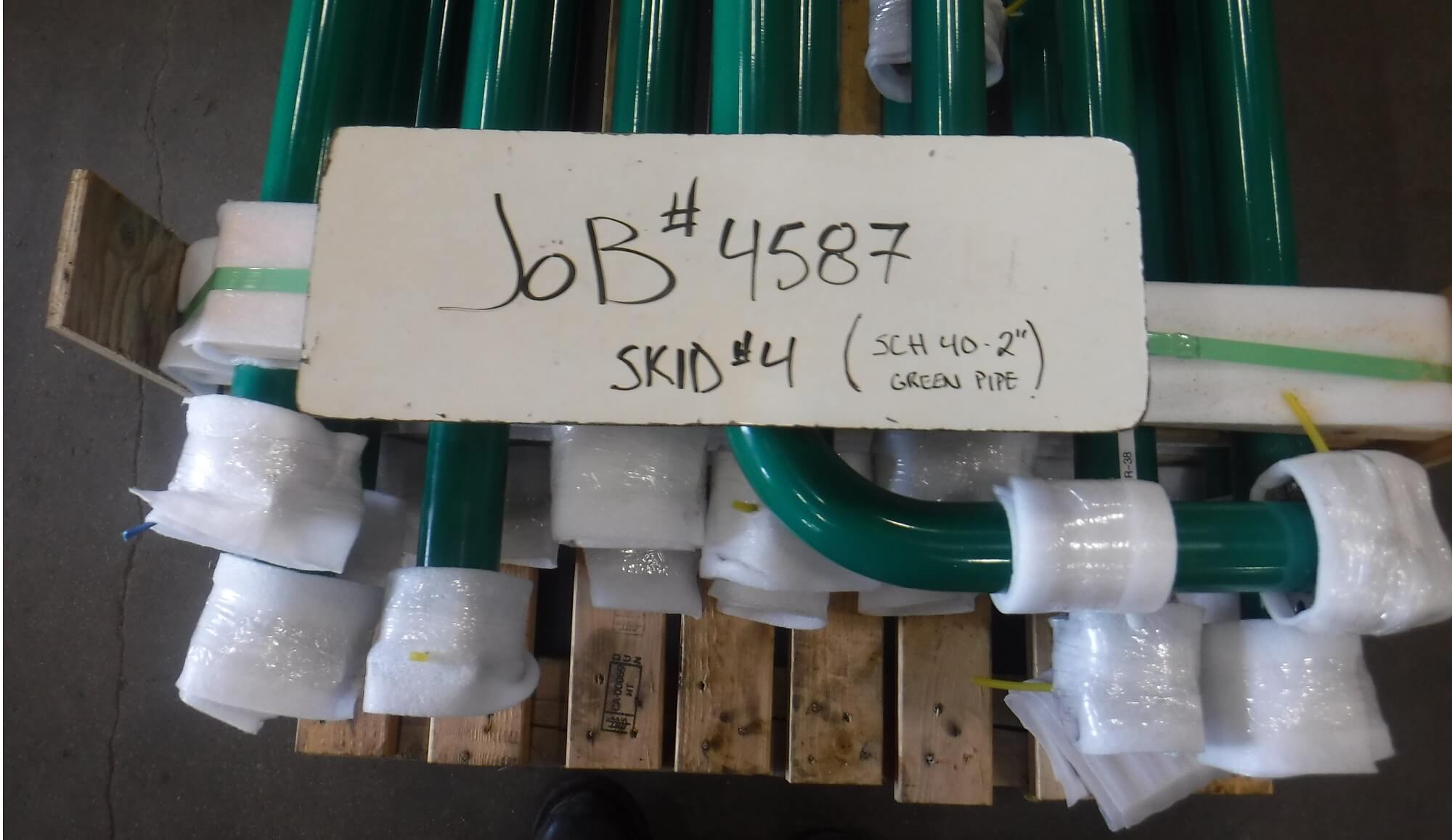

Prefabrication is a process where pipes are pre-designed,fabricated cleaned, painted at the Tube-Mac® (TMI) Factory and shipped to the installation site. These pipes are shipped with special shipping plates and Special Anti Corrosive strips (as shown below).

The Special Anti Corrosion Strips (ZERUST®) combat corrosion by diffusing vapour corrosion inhibitors inside the pipe. Hence the pipe remains corrosion free during shipping and storage at site for installation at a later date.

Some of the advantages of Tube-Mac® pre-fabricated piping are shown below:

Pre-Designed

Pre-Designed

Clean

Clean

Better Project Control

Better Project Control

Reduced Time

Reduced Time

Unbeatable Value

Unbeatable Value

Tight Tolerances

Tight Tolerances

Pre-Designed

Pre-Designed

The pre-fabricated piping is designed by Tube-Mac®'s most experienced Engineers. This results in arriving at the best possible solution (pipe routing, valve locations) for the customer. Further, the customer gets a full-fledged documentation package which includes - Pipe Arrangement Drawing, BOM, Information Package, Test Reports with every Pre-Fabricated Project.

Clean

Clean

Pre-fabricated piping is extremely clean. Since, it goes through a round of flushing at the factory before being shipped, these pipes offer a superior standard of cleanliness and drastically reduce flushing time.

Better Project Control

Better Project Control

Project Management becomes simpler as the pipes are pre-designed and materials planned at the factory. There are no issues of project haults due to common factors like - material wastage, wrong procurement, material shortage or quality issues. Pre-fabricated piping is designed and its materials checked by Tube-Mac®'s Design and Engineering Team. The pipes are shipped by the date specified by Tube-Mac® and hence the pipes have to only be assembled at site eliminating a lot of uncertainities that come with site fabrication.

Reduced Time

Reduced Time

Pipes are fabricated comparitively quicker at the factory and needs only assembly at site. Further, the flushing time is drastically reduced as the pipes are already flushed at the factory.Hence, flushing is generally done at site to clean the system oil rather than to clean the pre-fabricated pipes. Hence, overall there is a huge time saving for the customer.

Unbeatable Value

Unbeatable Value

With Tube-Mac®'s years of experience and they having a strong relationship with a large number of raw material manufacturers, high quality materials are sourced at the best possible rates. This translates to increased value that the customer receives for the price they pay.

Tight Tolerances

Tight Tolerances

As the fabrication is done at the factory, it is manufactured with quality materials using cutting-edge equipment by skilled personnel. This results in a piping system having the best possible dimensional tolerances ultimately resulting in a reliable piping system.