Non-Welded Piping and Methods

Non-welded piping is a method of joining pipes without the use of traditional welding techniques. Among a number of methods available, the choice depends on factors such as the type of pipe material, the application intended, and installation requirements. Some of the popular ones being -

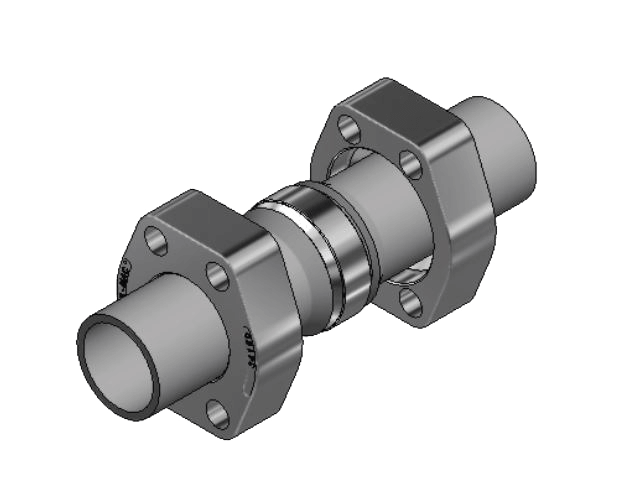

FLANGE CONNECTION

Pipes are connected using flanges by bolting them together. The flanges have raised surfaces with bolt holes that align when connected, creating a tight seal. Flanged connections are commonly used in industrial applications like hydraulics, lubrication, water etc for a range of pipe sizes ranging from ½” up to even 16”. A couple of examples being Tube-Mac’s 37 Degree Flare Flange System and Retain Ring Flange Systems which are meant for hydraulic and lubricating piping system.

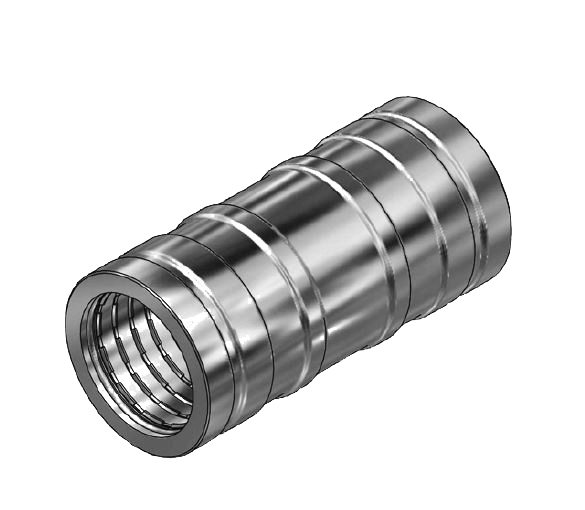

MECHANICAL JOINTS

Pipes are joined by using clamps or connectors. They may be permanently fixed or be dismantled. They are used generally in industrial piping systems and for medium size ranges from 1-1/2" to 6". One such method beingPyplok®which is a mechanically attached fitting with elastomeric seal and provides pressure ratings up to 9300 psi. It is used for wide range of applications like hydraulic piping, fire protection systems, and piping which involve high pressure.

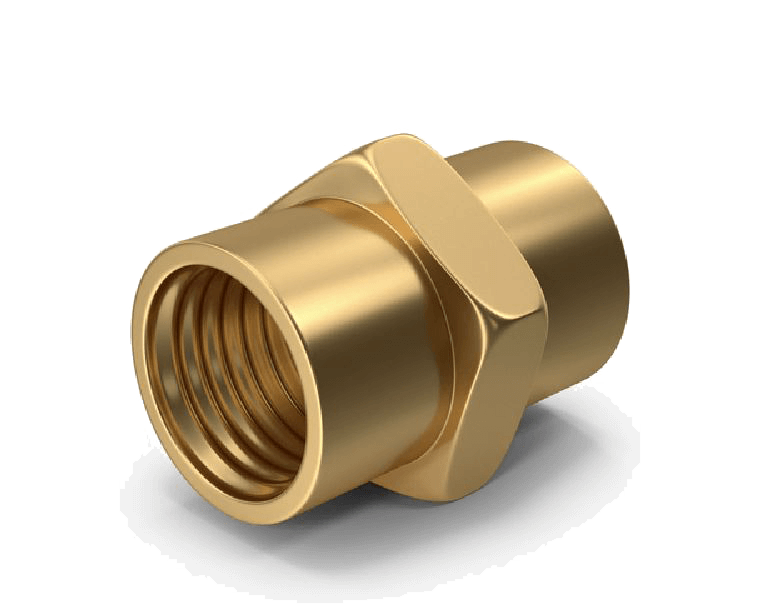

THREADED FITTINGS

Pipes and fittings come with male and female threaded ends that can be screwed together. It is generally used for pipes with small diameter and we can see its application in industrial systems, residential plumbing etc. The threads are made as per a specific industrial standard based on their application, location like NPT (National Pipe Thread) for North America, BSP (British Standard Pipe) for UK/Europe.

COMPRESSION FITTINGS

Here the fitting consists of a nut and ferrule that compresses onto the pipe to form a tight seal. This method is commonly used for metal (which can be formed) and plastic tubes like polyethylene