Case Study: Hydraulic Piping for Monopile Gripper: Singapore

Chase Resource (CR) was awarded the Monopile Gripper Piping Project by a leading offshore equipment manufacturer. This was a first-of-its-kind project for CR and a new challenge in its journey. Requirement of high standards and stringent timelines made it ideal for CR to be the preferred solutions provider for this project. Further, the experience, and capability CR brings in this field together with TMI Non-Welded Piping System cemented the project in CR’s favour.

Project Details were as follows:-

The scope of work was as follows:-

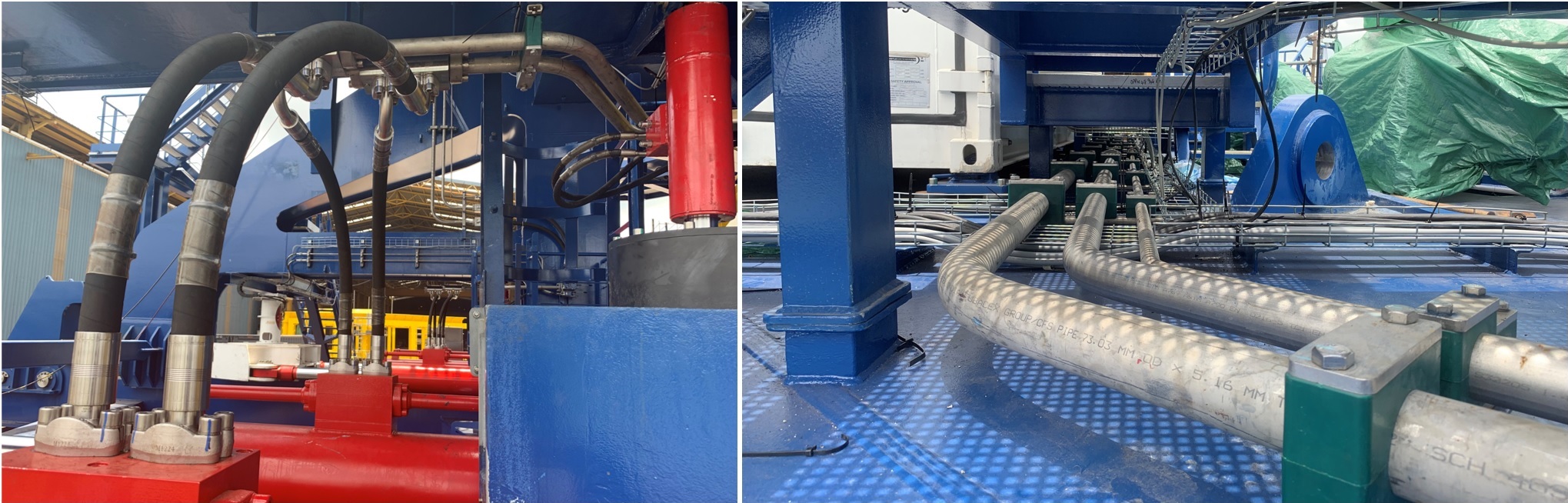

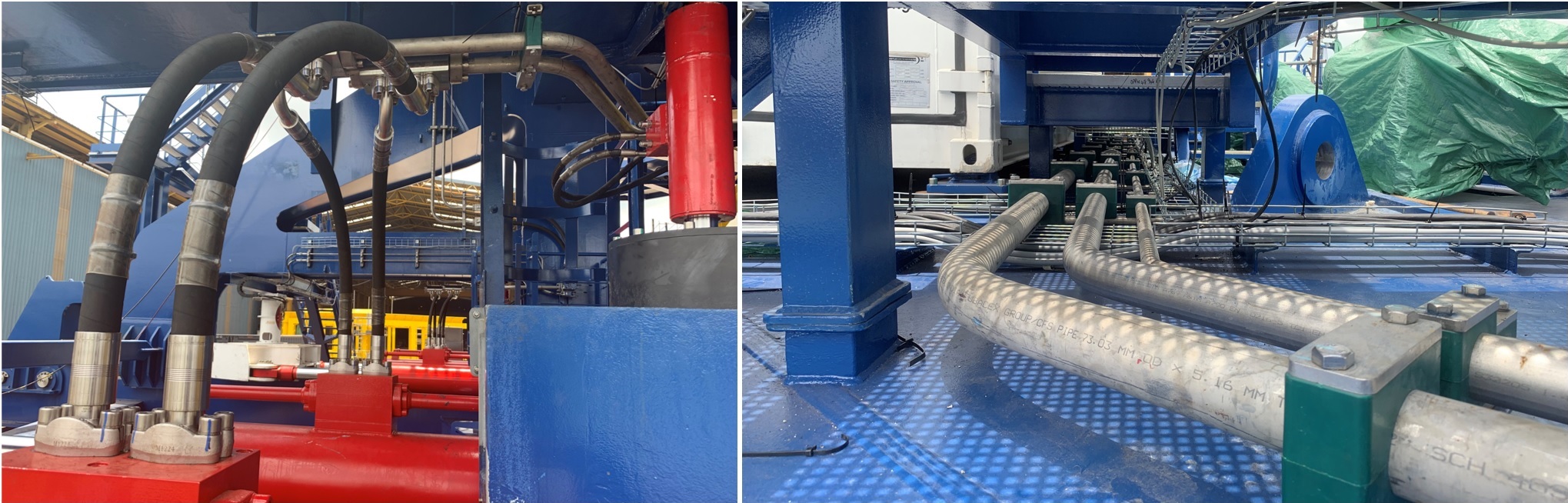

The job involved connecting the HPU which to the 14 cylinders that it powers and the total length of the piping being approximately 430 metres. Installation processes like bending, flaring, crimping, flushing, pressure test and hose fabrication was all carried out by CR’s inhouse team and equipment.

CR successfully delivered the system which was positively acknowledged by the customer.

Chase Resource (CR) was awarded the Monopile Gripper Piping Project by a leading offshore equipment manufacturer. This was a first-of-its-kind project for CR and a new challenge in its journey. Requirement of high standards and stringent timelines made it ideal for CR to be the preferred solutions provider for this project. Further, the experience, and capability CR brings in this field together with TMI Non-Welded Piping System cemented the project in CR’s favour.

Project Details were as follows:-

- Non Weld Technology : 37 Degree Flare Flange, PYPLOK®

- Pipe Sizes : NPS — 2-1/2” Sch80, 2” Sch80, 2” Sch40, 1-1/2” Sch80, 1-1/2” Sch40, 1-1/4” Sch80, 3/4” Sch80, 3/4” Sch40, 1/2” Sch40

- System Pressure : 250 Bar

- Piping Length : Approx 430 mtr (All lines)

The scope of work was as follows:-

- Supply of Pipes, Non Welded Pipe Fittings, and all other components related to piping.

- Installation - Fabrication, Bending, Flaring, Erection, Pressure Testing, Flushing of the Hydraulic Piping System.

The job involved connecting the HPU which to the 14 cylinders that it powers and the total length of the piping being approximately 430 metres. Installation processes like bending, flaring, crimping, flushing, pressure test and hose fabrication was all carried out by CR’s inhouse team and equipment.

CR successfully delivered the system which was positively acknowledged by the customer.

Download the Project E-Book

DOWNLOAD E-BOOK