Smart Watch Web

SMART WATCH WEB

SmartWatchWeb is an advanced remote refinery monitorization system which allows immediate detection of external and internal gas and steam leaks in steam traps and valves. It also facilitates an increase in energy efficiency of steam and condensate networks as well as reduction of greenhouse effect.

This innovative refinery monitorization system has been developed and patented by BiTherm, can integrate up to 4 different sensors: ultrasound, temperature, pressure and conductivity. The company has made breakthroughs.

Its extraordinary high efficiency has allowed users to reduce 15% to 30% steam consumption which means a great impact concerning environmental protection and sustainable growth (reduction of GHG emissions).

Unlike others, BiTherm is the most complete intelligent steam trap in the market, including inbuilt connections up to 4 sensors (ultrasound, temperature, pressure, and backpressure) which means complete capability for monitoring and diagnosis.

Its inbuilt connectors for sensors (even pressure and back pressure sensors) simplify installation and maintenance.

This innovative refinery monitorization system has been developed and patented by BiTherm, can integrate up to 4 different sensors: ultrasound, temperature, pressure and conductivity. The company has made breakthroughs.

Its extraordinary high efficiency has allowed users to reduce 15% to 30% steam consumption which means a great impact concerning environmental protection and sustainable growth (reduction of GHG emissions).

Unlike others, BiTherm is the most complete intelligent steam trap in the market, including inbuilt connections up to 4 sensors (ultrasound, temperature, pressure, and backpressure) which means complete capability for monitoring and diagnosis.

Its inbuilt connectors for sensors (even pressure and back pressure sensors) simplify installation and maintenance.

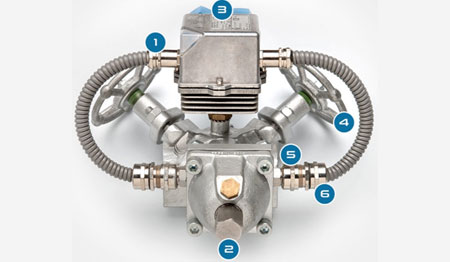

BiTherm Smart Watch Web Components

- Outlet pressure sensor

Condensate back pressure sensor - External adjustment mechanism

To set the operating temperature when the steam trap is running - SmartWatch® electronic device

Which also includes U&T sensors - Input & output lock valves

- Steam inlet connection

- Inlet pressure sensor traps

There are two ways in which the information from the SmartWatchWeb is transmitted as below:

Wired Architecture

This is the most powerful monitoring architecture due to the following aspects:

Complete monitoring of steam traps including the three characteristic parameters, which affect steam traps operation (Ultrasound, Temperature, and Backpressure). Wireless only includes Ultrasound and Temperature due to battery life.Reduced installation costs: up to 64 monitored elements linked to the same cable, which includes power supply and data transmissions.

Reliability: Interferences free (piping, structures, obstacles, buildings, etc).

Sample collection: Sampling rate is not limited by battery life (real time).

Reduction of maintenance cost: Neither replacement of batteries nor maintenance of radio transmitters.

Easy commissioning: High qualified wireless staff is not required.

Wireless Architecture

This option requires considering the following design aspects:

Partial monitoring of steam traps: It only includes two parameters (Ultrasound, Temperature) due to battery life.

Installation costs: Besides one wireless transmitter per element, wired Access Points need to be considered (It is important to highlight that wireless architectures are based on access points, which require to be powered by wire and optical fibe for data transmission).

Reliability: Study of environment (piping, structures, obstacles, buildings, etc).

Sample collection: Sampling rate affects battery life.

Maintenance cost: Replacement of batteries and maintenance of radio transmitters to be considered.

Commissioning: High qualified wireless staff is required.

Partial monitoring of steam traps: It only includes two parameters (Ultrasound, Temperature) due to battery life.

Installation costs: Besides one wireless transmitter per element, wired Access Points need to be considered (It is important to highlight that wireless architectures are based on access points, which require to be powered by wire and optical fibe for data transmission).

Reliability: Study of environment (piping, structures, obstacles, buildings, etc).

Sample collection: Sampling rate affects battery life.

Maintenance cost: Replacement of batteries and maintenance of radio transmitters to be considered.

Commissioning: High qualified wireless staff is required.