Stainless Steel Fittings & Components

Hydraulic Fittings & Pneumatic Fittings

DIN 2353 Ferrule

Pipe Threaded Fittings

JIC 37° Flare Fittings

Compression Fittings

Push In/On Connectors

SAE & DIN Flanges

BSPP 60° Hose Connectors

Quick Connect Couplings

Hose

Hose Fittings

CAMLOK

Valves

Measurement & Control Systems

Pipe Couplings

Butt Weld Fittings

Instrumentation Fittings

U2-Lok Twin Ferrule Fittings

Clino Aseptic Connections

Ecotube Couplings

Orbital Weld Fittings

V-C Couplings

Vacuum

Zero Con

Small Flange Connection

Sanitary

Aquapress Compression

Shoulder Coupling

Please click here to access the general brochure.

Features

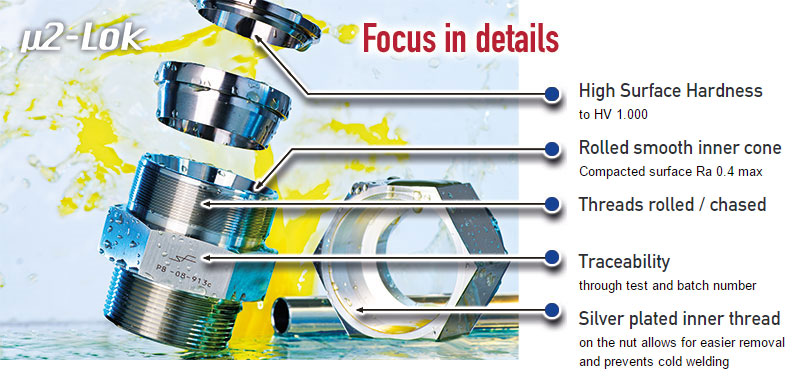

Schwer’s Product Managers and development engineers are constantly optimising and upgrading their fittings in order to provide products created specifically to match the customers’ requirements.

All Schwer, products are branded with brand mark, material and batch number using laser labelling technique.

Generally, all parts, that make contact with the media, are marked with a test number using a laser. This number conceals a wealth of information. After many years, it’s still possible to match the mechanical tests to the original material and offer the required material certificates.

Generally, all parts, that make contact with the media, are marked with a test number using a laser. This number conceals a wealth of information. After many years, it’s still possible to match the mechanical tests to the original material and offer the required material certificates.

Approvals

Schwer Fittings are GL Approved, DNV GL Approved and GOST Approved as shown below.

Type Approval For Compression Fittings & Twin Ferrule Fittings

Type Approval For Compression Fittings & Twin Ferrule Fittings

Gost Certification

Applications

With an extensive and growing product range, and many possible applications, Schwer supplies to many different industries. Clients include multi-national corporations as well as small and medium sized businesses worldwide.

Through personal contacts and customer recommendations, they can look back on many long standing partnerships and build on a solid base for the future. Experience with Kanban solutions, ensures a smooth process in the use and delivery of their products.

Their specially developed and patented cavity free Ecotube couplings are mainly used when smooth and piggable connections of assemblies are necessary. They are used, as standard, in paint lines and lacquering operations by major manufacturers. The stainless steel fittings and components are intended primarily for hydraulic gas and fluid applications, and are used, amongst others, in the following:

Hydraulic and Pneumatic

Through personal contacts and customer recommendations, they can look back on many long standing partnerships and build on a solid base for the future. Experience with Kanban solutions, ensures a smooth process in the use and delivery of their products.

Their specially developed and patented cavity free Ecotube couplings are mainly used when smooth and piggable connections of assemblies are necessary. They are used, as standard, in paint lines and lacquering operations by major manufacturers. The stainless steel fittings and components are intended primarily for hydraulic gas and fluid applications, and are used, amongst others, in the following:

Hydraulic and Pneumatic

- Automotive

- Fluid Technology

- Hydraulic and Pneumatic Machinery

- Industrial Plant Construction

- Paint lines

- Paper mills

- Ship Building and Offshore Industries

- Environmental Engineering

- Wind Farms

Instrumentation

- Chemical, Biotechnical and Pharmaceutical

- Laboratories

- Process Engineering, Food Industry

- Aeronautics and Astronautics

- Reactors

- Solar Power

- Vacuum Technology

- Packaging Technology

Sanitary

- Industrial Plant Construction

- Pipe Line Construction

- Compressed Air Technology

- Sanitary Industry