Prefabrication

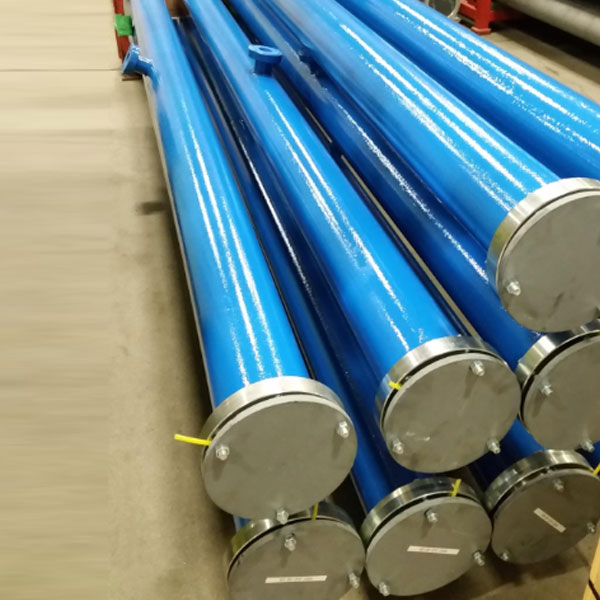

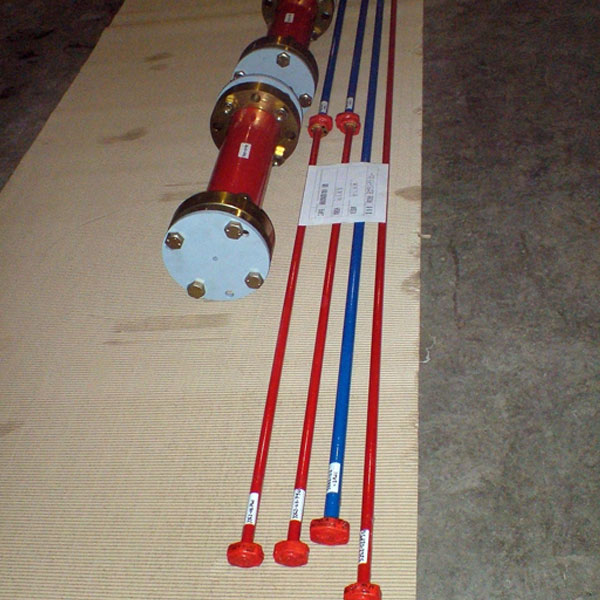

Prefabrication is a process where pipes are fabricated at the TMI Factory, cleaned, painted and shipped to the installation site. These pipes (pre-fabricated piping) are shipped with special shipping plates and Special Anti Corrosive strips (as shown below).

The Special Anti Corrosion Strips combat corrosion by diffusing vapour corrosion inhibitors inside the pipe. Hence the pipe remains corrosion free during shipping and storage at site for installation at a later date.

TMI Prefabricated Piping Systems are mainly used in projects which are based on the below:

1. No Space Constraints

Pre-fabricated piping is preferred on sites where there is no possibility of obstruction in the routing for our piping to be installed. Obstructions may be either caused due to other pipelines that are already installed close to the route where our piping has to be installed or due to presence of fixed equipments near the pipe routing.

2. Pre-Designed

Pre-fabricated piping is preferred in projects where the pipe routing is pre-designed. This helps to manufacture pipes with less tolerance since they are fabricated in the TMI factory.

3. Cleanliness Demand

Pre-fabricated piping is preferred at projects where there is high demand for cleanliness like simulation labs, pharmaceutical plants, food & beverage plants.

4. Control Over Cost

Pre-fabricated piping is preferred for projects with a specific budget, since the price is already known there will not be any extra pipe additions which is a relief to the customer.

5. Quick Installation

Pre-fabricated piping is preferred where the piping system should be installed in a short span of time. Pre-fabrication drastically reduces installation time.

1. No Space Constraints

Pre-fabricated piping is preferred on sites where there is no possibility of obstruction in the routing for our piping to be installed. Obstructions may be either caused due to other pipelines that are already installed close to the route where our piping has to be installed or due to presence of fixed equipments near the pipe routing.

2. Pre-Designed

Pre-fabricated piping is preferred in projects where the pipe routing is pre-designed. This helps to manufacture pipes with less tolerance since they are fabricated in the TMI factory.

3. Cleanliness Demand

Pre-fabricated piping is preferred at projects where there is high demand for cleanliness like simulation labs, pharmaceutical plants, food & beverage plants.

4. Control Over Cost

Pre-fabricated piping is preferred for projects with a specific budget, since the price is already known there will not be any extra pipe additions which is a relief to the customer.

5. Quick Installation

Pre-fabricated piping is preferred where the piping system should be installed in a short span of time. Pre-fabrication drastically reduces installation time.