pyplok® trial installation for instrumentation lines

Pyplok® Case Study: Pyplok® Trial Installation for Instrumentation Lines

Problems encountered:

Problems encountered:

The existing method of pipe connection at the manifold was by threading as no hot work was permitted at this time. The total number of man hours expected to complete the installation by threading method was approximately 48 man hours.

Furthermore, as the connections are by threading, there may be leaks during test as some of the joints might not be properly tightened.

If such leaks occur, then repair work must be carried out. If the leak happened to be at one end, and the pipe connection does not have a union joint, then it is very tedious to tighten the leaking joint. The whole line might have to be unscrewed and then tightened and tested again.

Pyplok® being a tamper proof and fool proof fitting with no threads was believed to be reliable for such systems and hence was asked for a trial installation at the South Furious Drilling Platform.

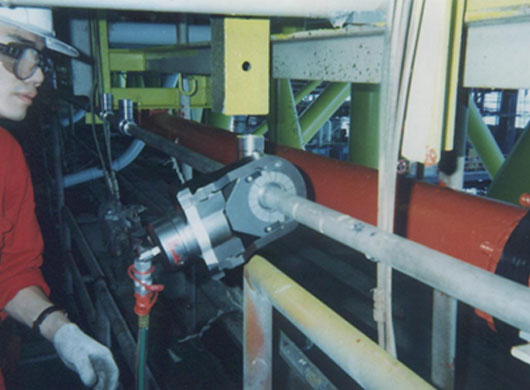

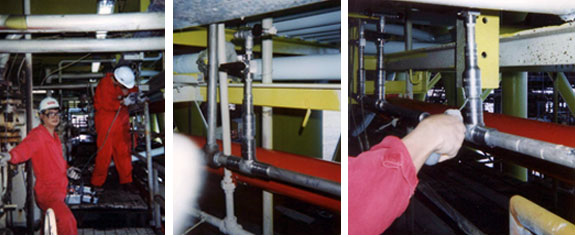

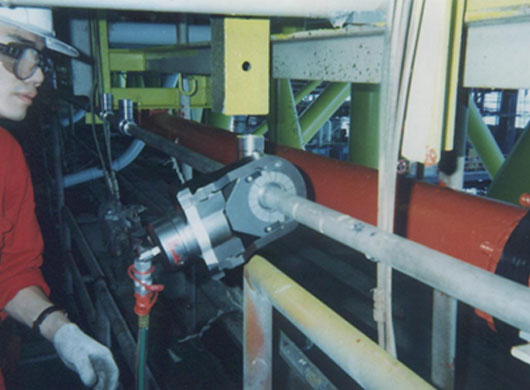

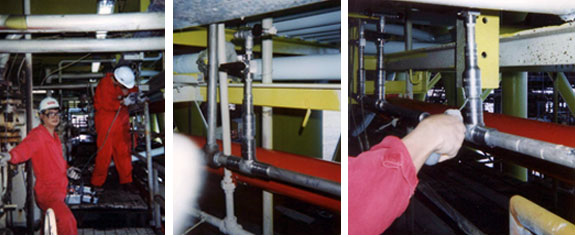

The steps involved were:

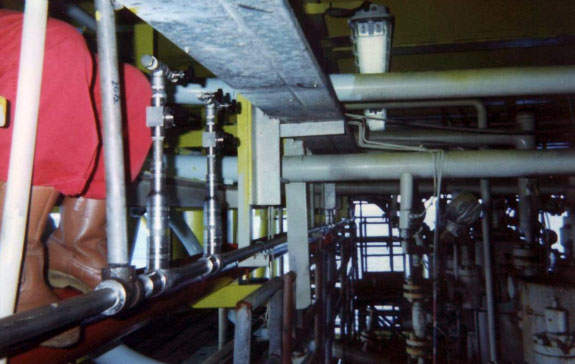

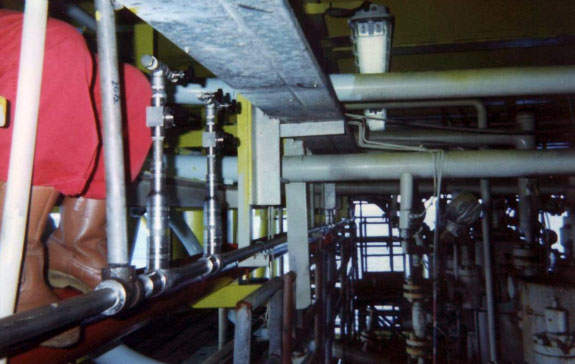

View of the completed line

Conclusion from Customer:

The major advantage of using Pyplok® lies in the method and installation time. Since no hot work and threading are required, the installation time was greatly reduced when compared to more conventional methods such as welding or threading.

The installation easily took 3 ¼” to complete compared to threading joints which are more tedious and extremely time consuming. This will help in saving of man-hour costs as well as the improvement of safety and working conditions. Also, there are virtually no rework or NDT costs.

Furthermore, the use of Pyplok® eliminates the need for welding, brazing, NDT, gas freeing, fire watches and rework while providing a system of greater integrity.

Location – South Furious Drilling Platform, Sabah High Sea, Sarawak

Scope of Work – Installation of Pyplok® Connectors for Instrumentation Manifolds

Piping Specs – ½”NPS and 1”NPS Sch 80 Stainless Steel

Operating Pressure – 100 psi

Scope of Work – Installation of Pyplok® Connectors for Instrumentation Manifolds

Piping Specs – ½”NPS and 1”NPS Sch 80 Stainless Steel

Operating Pressure – 100 psi

The existing method of pipe connection at the manifold was by threading as no hot work was permitted at this time. The total number of man hours expected to complete the installation by threading method was approximately 48 man hours.

Furthermore, as the connections are by threading, there may be leaks during test as some of the joints might not be properly tightened.

If such leaks occur, then repair work must be carried out. If the leak happened to be at one end, and the pipe connection does not have a union joint, then it is very tedious to tighten the leaking joint. The whole line might have to be unscrewed and then tightened and tested again.

Pyplok® being a tamper proof and fool proof fitting with no threads was believed to be reliable for such systems and hence was asked for a trial installation at the South Furious Drilling Platform.

The steps involved were:

- Material Preparation

- Initial Training and brief product introduction conducted to instrumentation supervisor, team leaders and technicians.

- Crimping of ½”NPS x 1”NPS Reducer onto pipes in the workshop.

- Completed 6 Sections, each section comprising of a tee, both ends to pipe and one end to the reducer bushing.

- Pressure Testing of the fittings were done and no leaks found out.

View of the completed line

| Fitting Description | Part Number | Amount Used |

| 1” x ½” NPS Reducer | DM20101K1608 | 13 |

| 1” NPS Tee | DM20004K16 | 13 |

| 1” NPS 90° Elbow | DM20003K16 | 2 |

Conclusion from Customer:

The major advantage of using Pyplok® lies in the method and installation time. Since no hot work and threading are required, the installation time was greatly reduced when compared to more conventional methods such as welding or threading.

The installation easily took 3 ¼” to complete compared to threading joints which are more tedious and extremely time consuming. This will help in saving of man-hour costs as well as the improvement of safety and working conditions. Also, there are virtually no rework or NDT costs.

Furthermore, the use of Pyplok® eliminates the need for welding, brazing, NDT, gas freeing, fire watches and rework while providing a system of greater integrity.