Pyplok® in Offshore

With demand for energy growing day by day, the need for exploration in deep sea offshore has only been increasing. However, these environments pose a lot of challenges when it comes to building and maintaining drilling and extraction infrastructure. Piping being a crucial component, its installation and maintenance in offshore conditions is a challenging task that many customers/contractors face. The harsh weather along with a highly corrosive environment makes maintenance and up-keep very demanding.

The major challenges faced by contractors/customers when it comes to their piping system are as shown below -

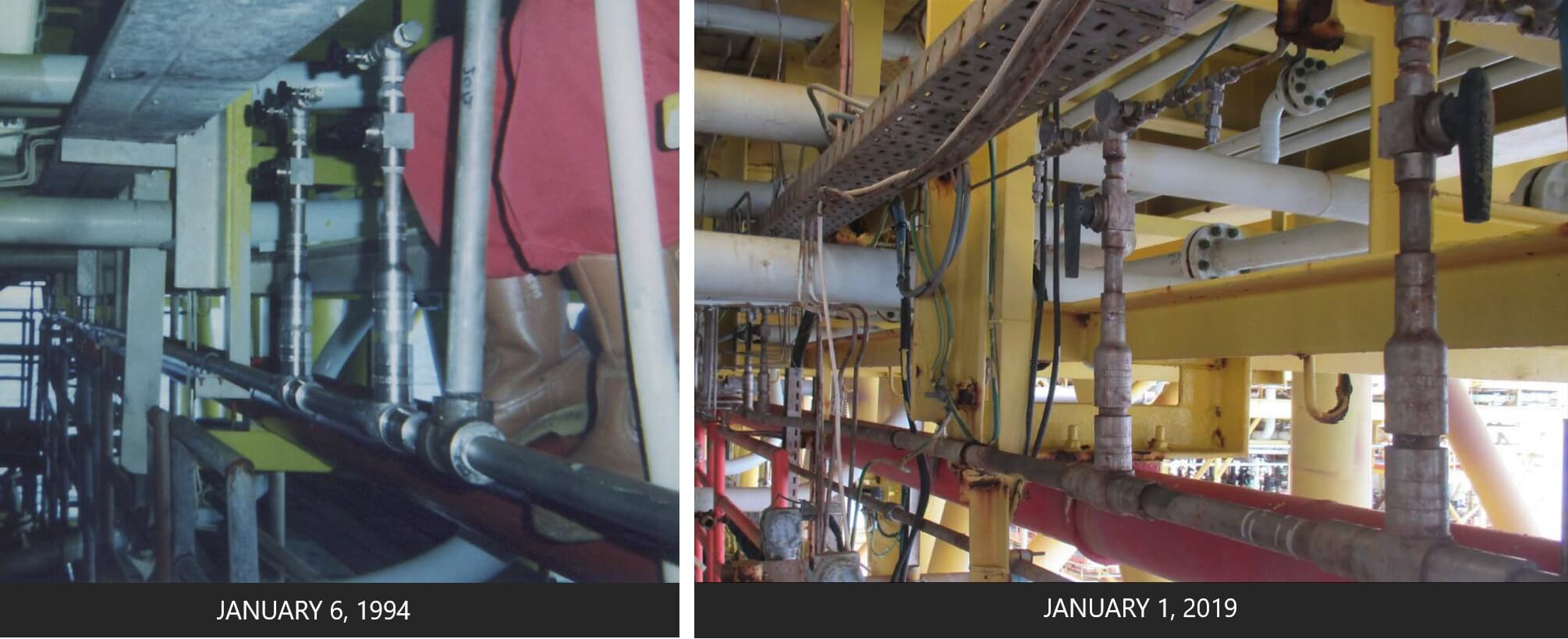

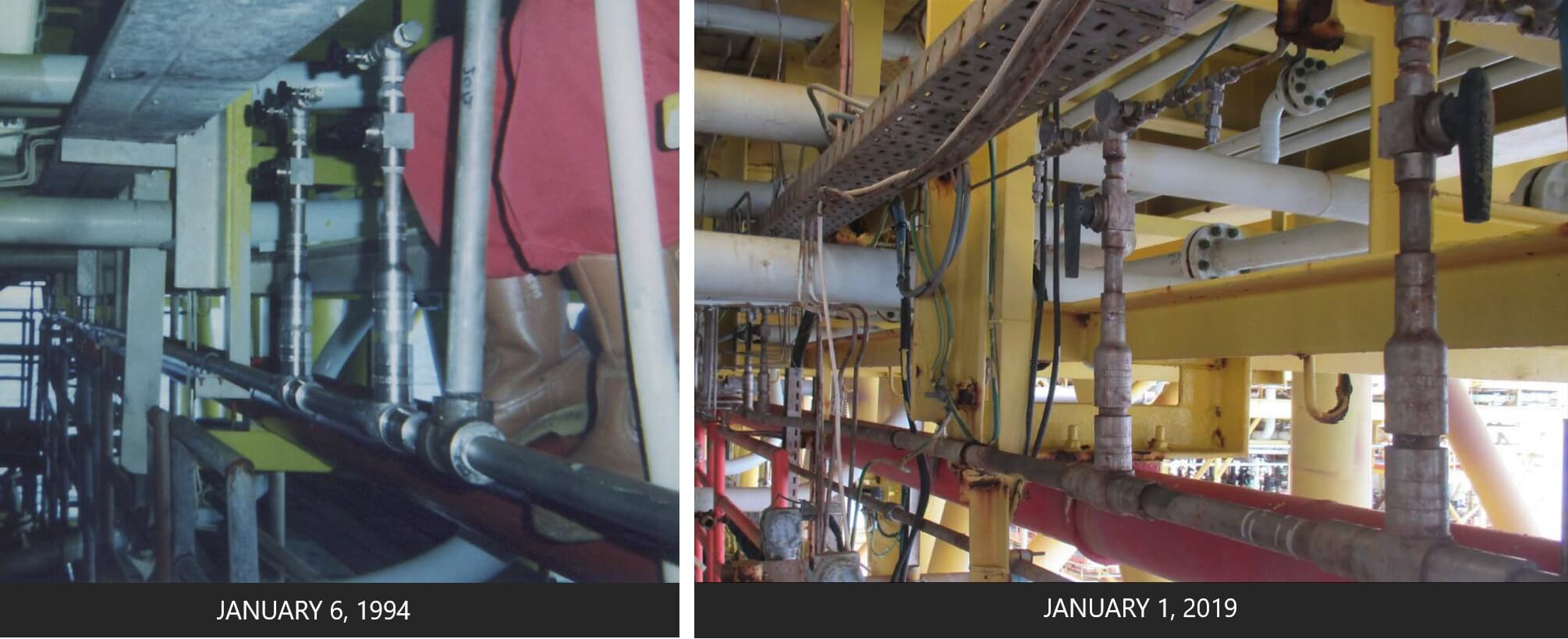

Pyplok® is a 360 degree radially swaged mechanically attached fitting, it is easy to install, fast and involves no hot work. Thus, the installers need no special skills to operate the tool and install the fitting. It is available in CS, SS, Cu-Ni 70/30 & 90/10, Duplex 2205 and Super Duplex 2207 thus able to cater to high corrosive environments. Sizes available range from 1/4” OD to 4” NPS Pipe. Further, PYPLOK® has proved 25+ years of service in an offshore application as it is successfully serving the South Furious Platform - Shell Sarawak for the instrument manifold P-pilot lines (pics shown below).

The above qualities of Pyplok® make it an ideal pipe/tube fitting for offshore applications. Pyplok® is approved by Shell Brunei, Shell Malaysia, Shell Eastern, StatOil and Woodside which makes it a reliable and popular fitting across the Oil & Gas Offshore space.

The major challenges faced by contractors/customers when it comes to their piping system are as shown below -

- Less time for repair or shutdown

- Avoid hot work

- Corrosion

- Skilled Labour

- Reliability

Pyplok® is a 360 degree radially swaged mechanically attached fitting, it is easy to install, fast and involves no hot work. Thus, the installers need no special skills to operate the tool and install the fitting. It is available in CS, SS, Cu-Ni 70/30 & 90/10, Duplex 2205 and Super Duplex 2207 thus able to cater to high corrosive environments. Sizes available range from 1/4” OD to 4” NPS Pipe. Further, PYPLOK® has proved 25+ years of service in an offshore application as it is successfully serving the South Furious Platform - Shell Sarawak for the instrument manifold P-pilot lines (pics shown below).

The above qualities of Pyplok® make it an ideal pipe/tube fitting for offshore applications. Pyplok® is approved by Shell Brunei, Shell Malaysia, Shell Eastern, StatOil and Woodside which makes it a reliable and popular fitting across the Oil & Gas Offshore space.

25 Years of Photo Comparison of the air instrumentation line which was installed way back in 1994 and still running with no leaks

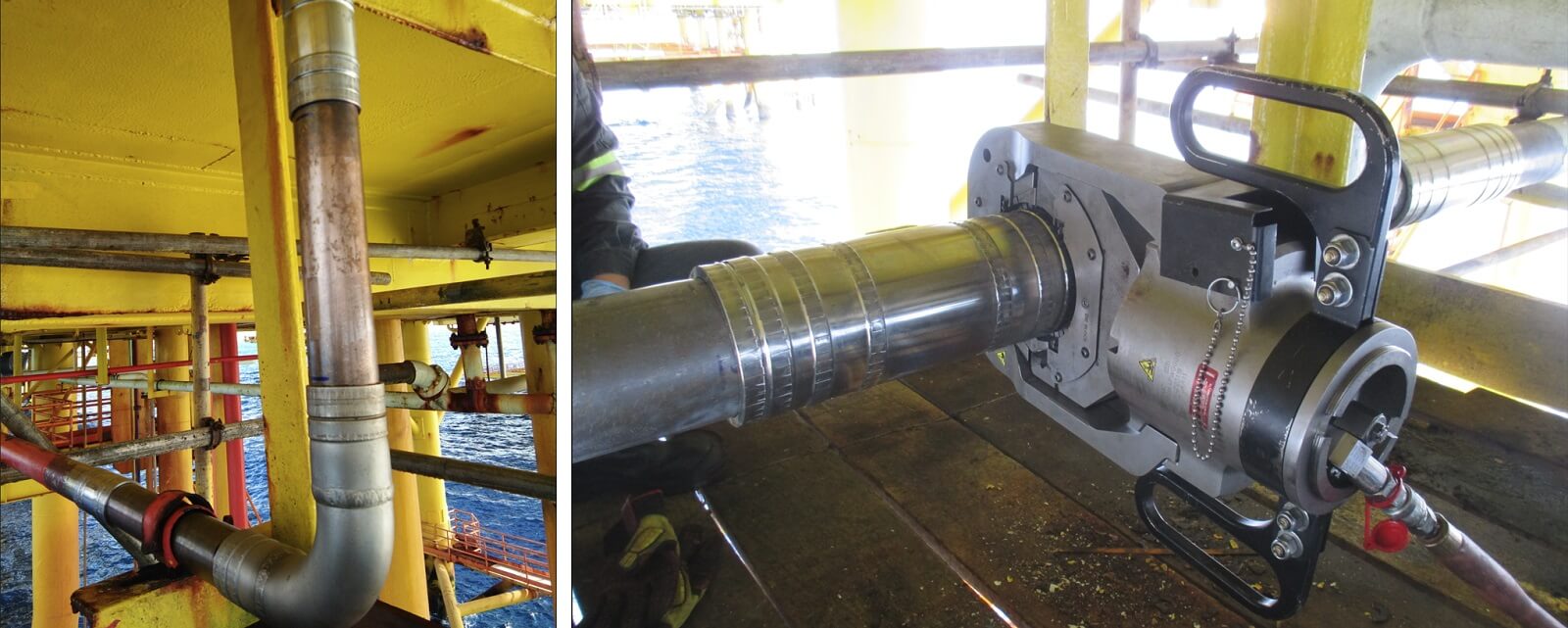

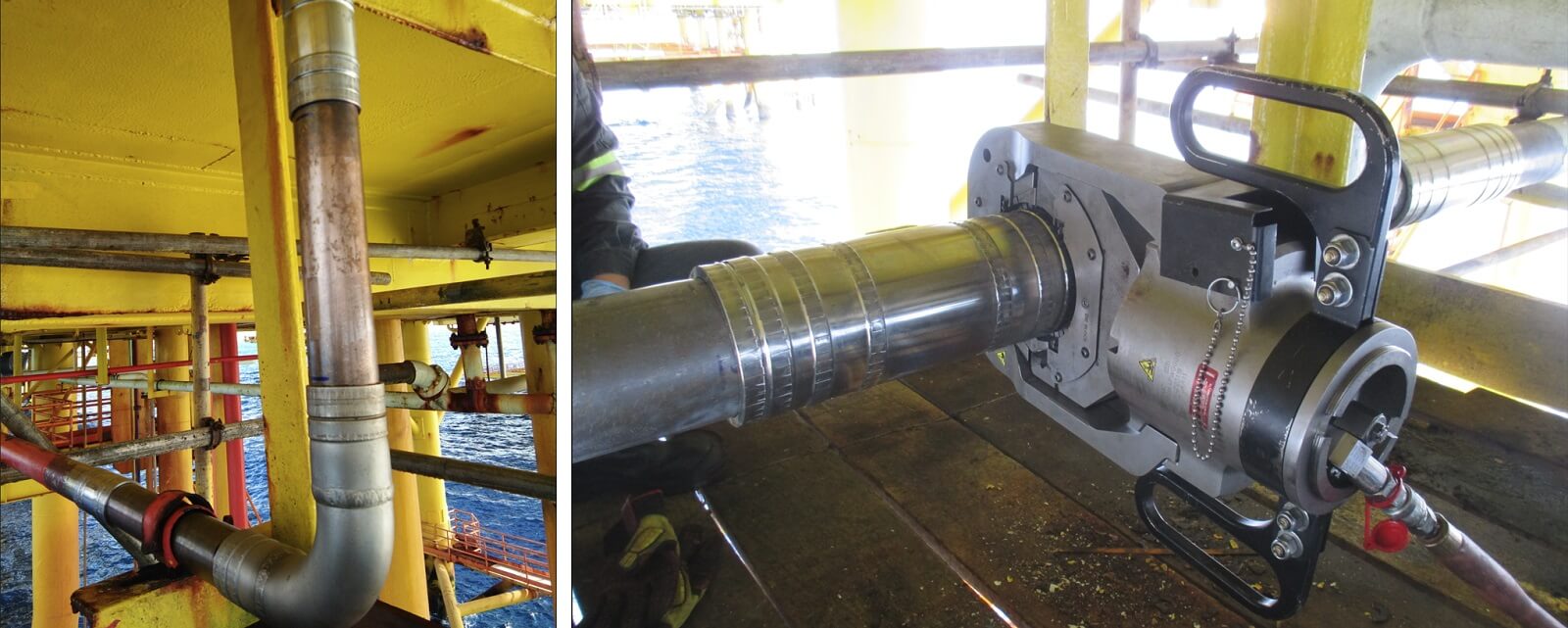

Pyplok® installed at Shell Sarawak's E11 Complex. Left Image- Cu-Ni Pyplok® installation for Firewater line. Right Image - 4" Pyplok® installation.

Download the E-Book

DOWNLOAD E-BOOK