Pipe Grooving machine

PIPE Grooving machine

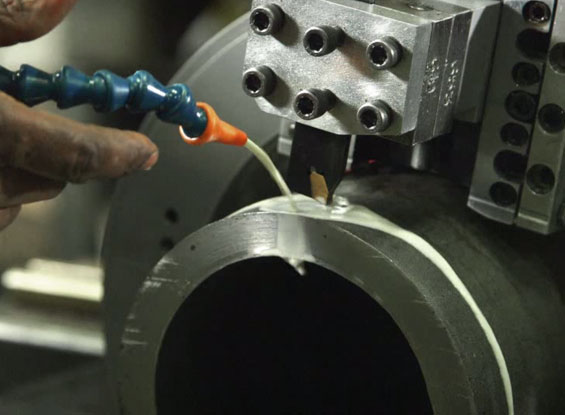

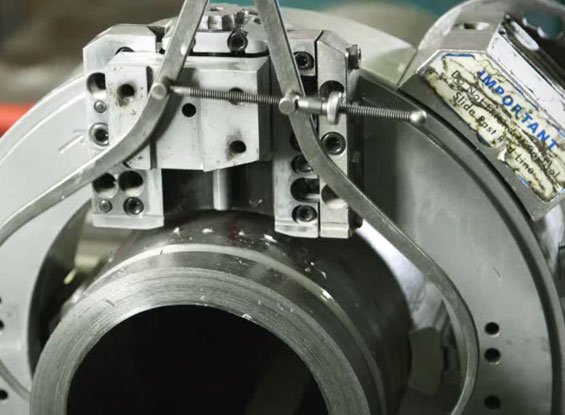

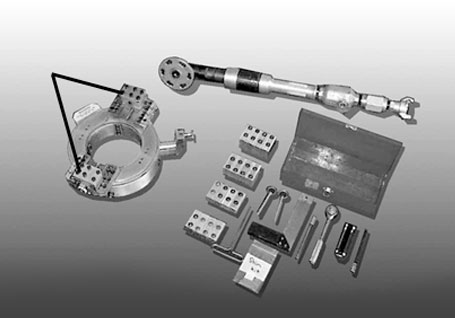

The Grooving Machine is a Low Clearance Split Frame Machine (LCSF) which is a portable pipe cutting and bevelling system developed for on-site operation. The LCSF uses lathe type machining principles, with capabilities for cutting (sever process), bevelling (form tool or single point), and counter- boring.

Set-up and operation is quick and simple, and the Pipe Grooving Machine requires little maintenance other than lubrication. Split frame prepping is a safe, clean operation that neither affects the metallurgical qualities of the metal nor places airborne contaminants in the environment.

Set-up and operation is quick and simple, and the Pipe Grooving Machine requires little maintenance other than lubrication. Split frame prepping is a safe, clean operation that neither affects the metallurgical qualities of the metal nor places airborne contaminants in the environment.

Pipe Grooving Machine Features

- Simple, lightweight, rugged design for cutting and prepping in tight places.

- Works on all sizes, wall thicknesses, and material across the entire range of pipe diameter capacities.

- Self-squaring clamping system for easy set-up.

- Safe cold-cutting for use in any environment.

- Standard air motor drive with options for hydraulic or electric power.

- Adjustable bearings and hardened bearing raceways for maximum dependability and perfor- mance.

- Modular accessories for counterboring, compound bevelling, J-prepping, heavy-wall cutting, and internal cutting.

- Remote operation capability with optional control module.

Pipe Grooving Machine Models and Model Designation

The low clearance split frame (LCSF) consists of 15 models for cutting and bevelling pipes from 2” (51 mm) to 48” (1219 mm) outside diameter. Each model covers a range of pipe sizes, as described in Table 1.

The numbering system of the machines are as follows:

Type: 60-000-08

Model: SF 408/3

Serial: 06-1234 (Example)

“SF” Designates Wachs Low Clearance Split Frame Machine, followed by the capacity of the Pipe Grooving Machine, and “/3” which designates the generation of design.

The following numbers indicate the capacity:

- 204 will mount on 2” through 4” pipe

- 206 will mount on 2” through 6” pipe

- 1016 will mount on 10” through 16” pipe

manual